HANDS-ON WORKSHOP IN 3D-printing & Microfluidics for BIOENGINEERING

May 27–29, 2025

MCGILL UNIVERSITY

Overview

Course Content

Schedule

Keynote Lecture

Location

Participant Feedback

Meet Our Team

Sponsors

Overview

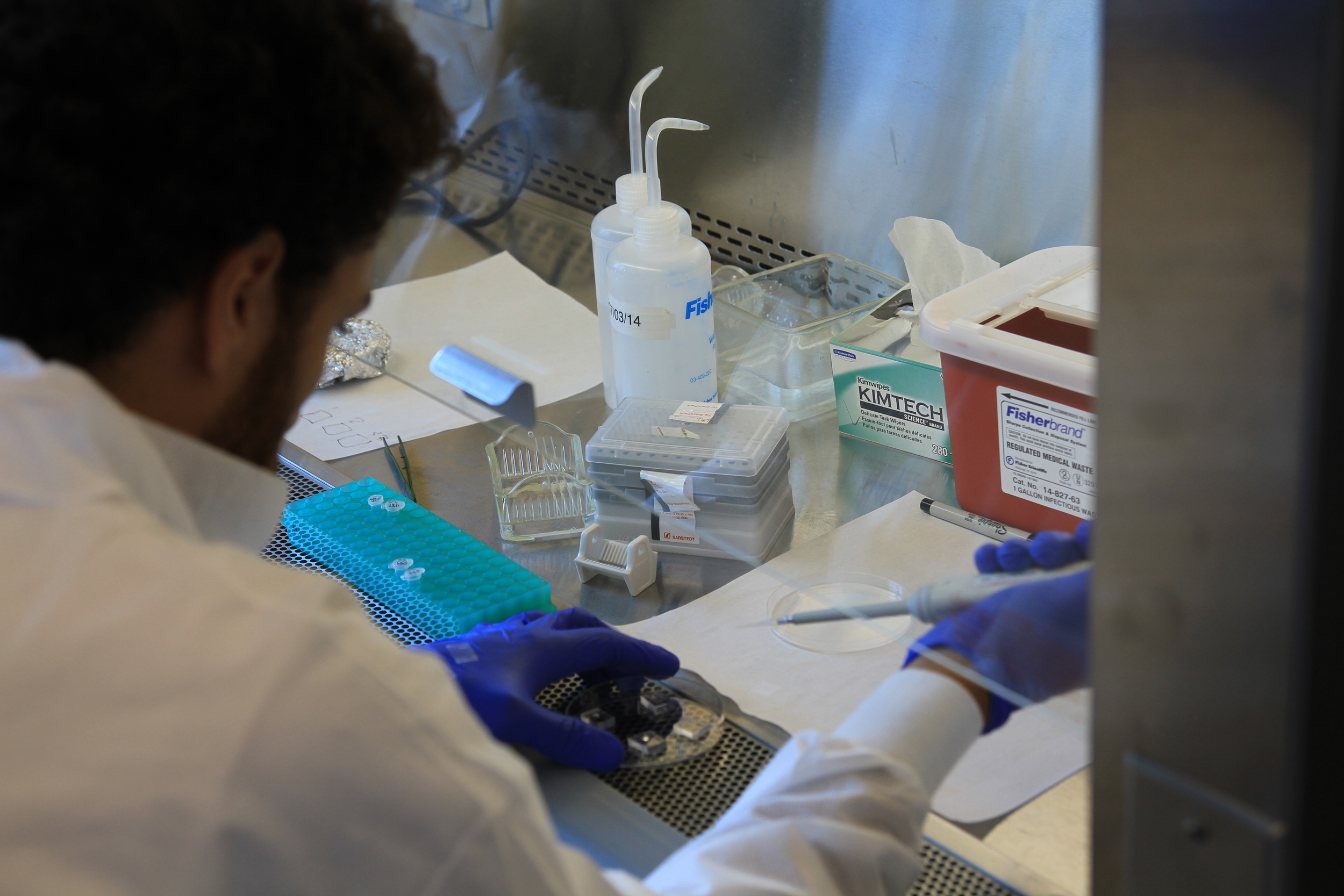

The 15th annual Hand's on Workshop in Micro and Nano Bioengineering will be held in May 27–29, 2025 at McGill Univeristy in Montréal, Québec. Participants will learn the foundations of micro and nano biotechnologies and gain first hand experience with Computer Aided Design (CAD), 3D printing, soft lithography, microfluidic cell culture and more. Our last workshop hosted 50 attendees from industry and academia partaking in the workshop and we look forward to having you join us this year!

The course is open to students, scientists, engineers, and industry professionals in any area of research who would like to learn more about micro and nanoscience technology in general. The course is of particular interest to biomedical researchers, chemists, physicists, as well as biomedical, mechanical, chemical, and materials engineers.

Open All | Close All

MODULE 1: LECTURES SERIES

The workshop will begin with an introduction on microfluidics and 3D printing techniques for biomedical applications. This year, we will highlight microfluidic 3D cell culture devices (organ-on-chip devices) as a showcase how engineering and the life sciences can benefit from each other. We will introduce their concept, current state of the art and give an outlook on some of the current research topics (e.g. modularity, continuous on-chip assays).

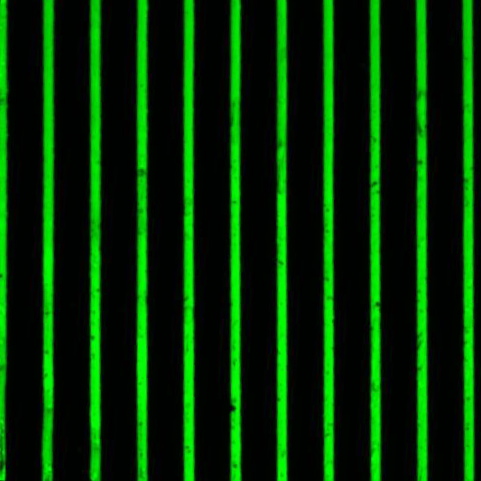

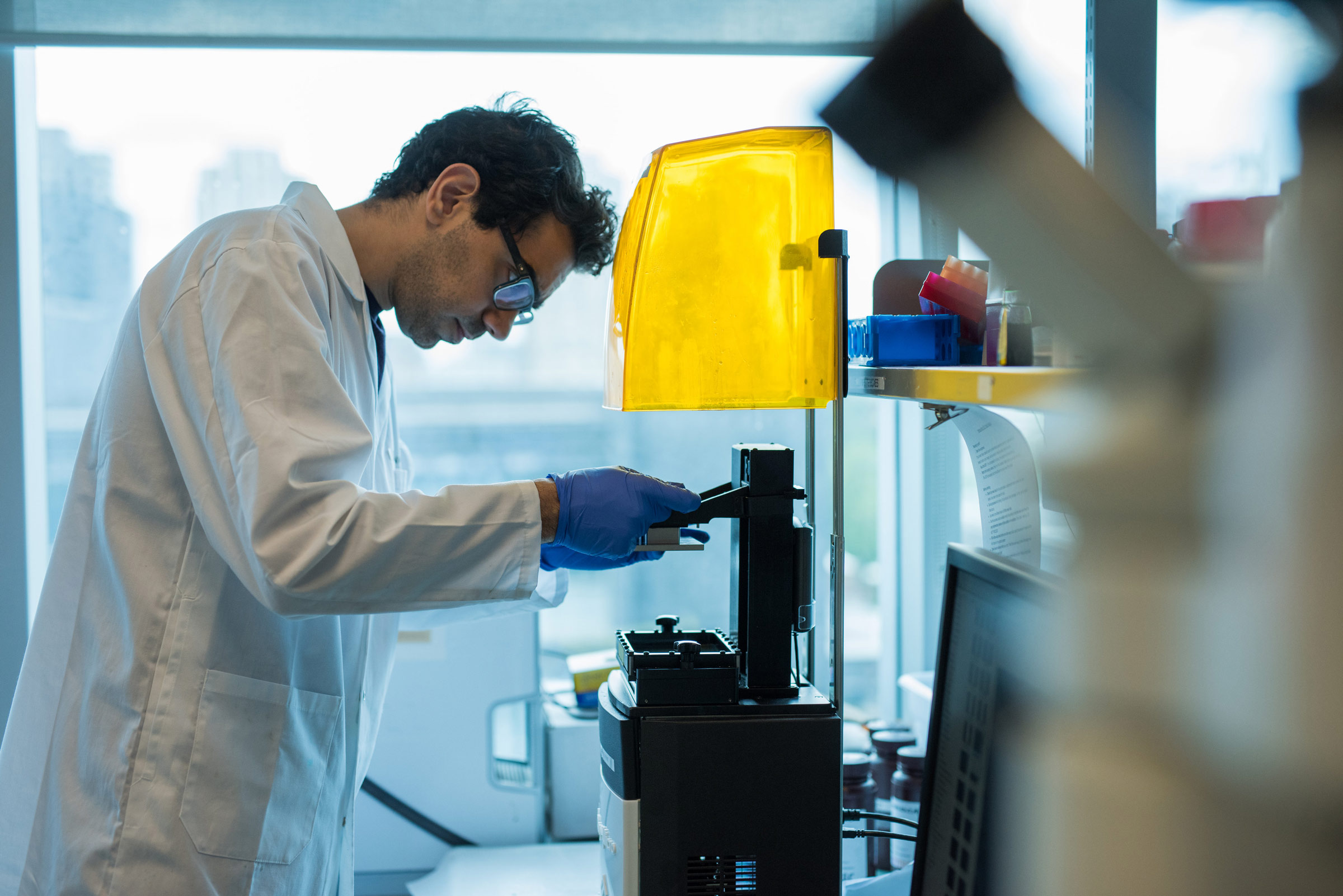

This will be followed by two in-depth lectures on the key engineering techniques behind them. The first one will be on microfluidics where we will cover the basics of fluid behaviour at the microscale and showcase common designs as well as workflows. In the second lecture we will cover the full range of common 3D printing techniques, including stereolithography and extrusion printing with a variety of biomaterials. The hands-on module and design challenge of the workshop will build on the content of these lectures.

MODULE 2: COMPUTER AIDED DESIGN (CAD) STUDIO

Participants will first learn the basics of Computer Aided Design (CAD) software (AutoCAD). Design rules and limitations will be discussed for high resolution 3D printing. In the interactive portion of the session, participants will design and make adjustments to a CAD model for a 3D printed microfluidic device with bioengineering applications. Participants are encouraged to design their proposed devices from the design challenge on the second workshop day and will have the chance to 3D print their devices during the final lab session. Computers are provided, however, participants are encouraged to bring their own laptops.

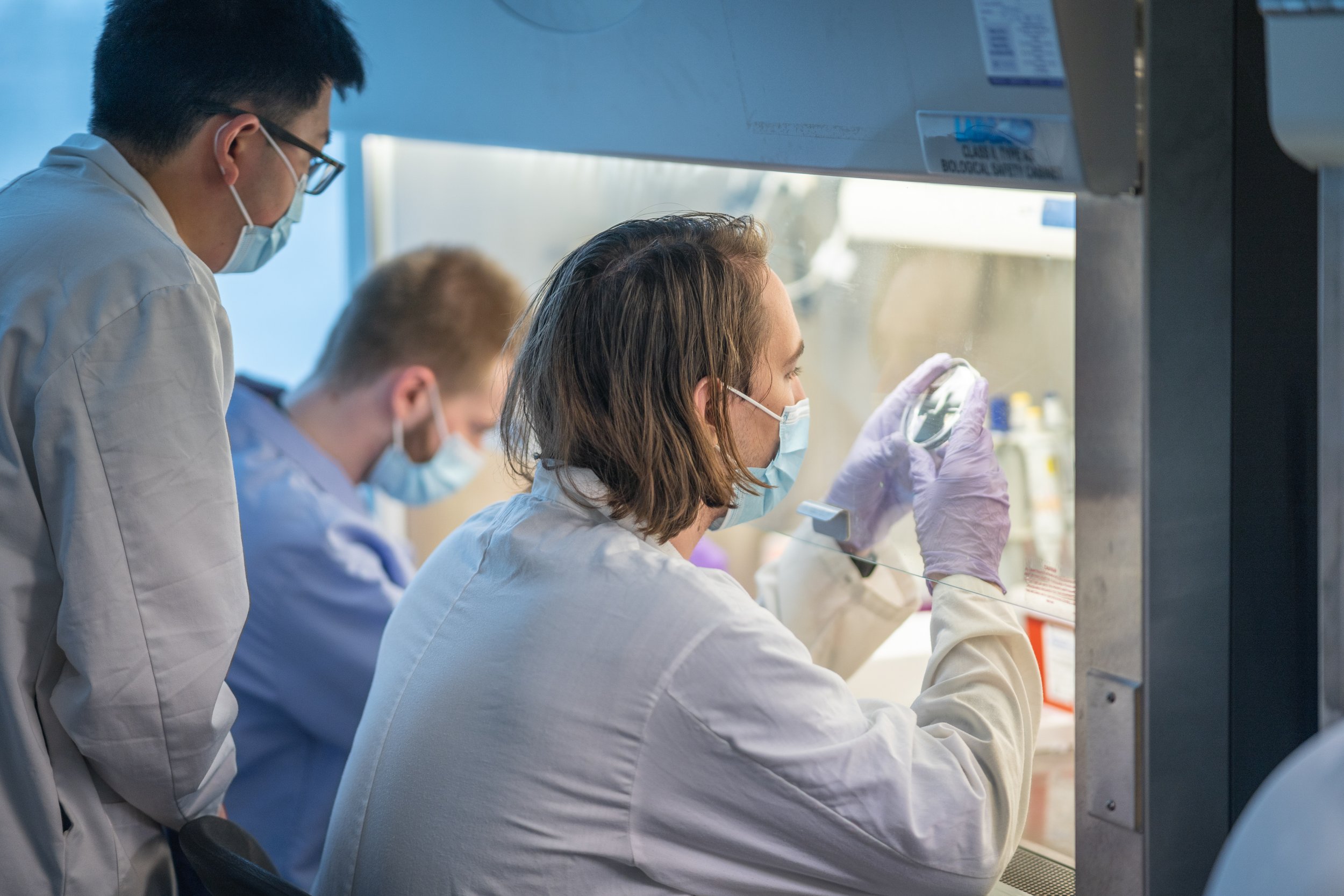

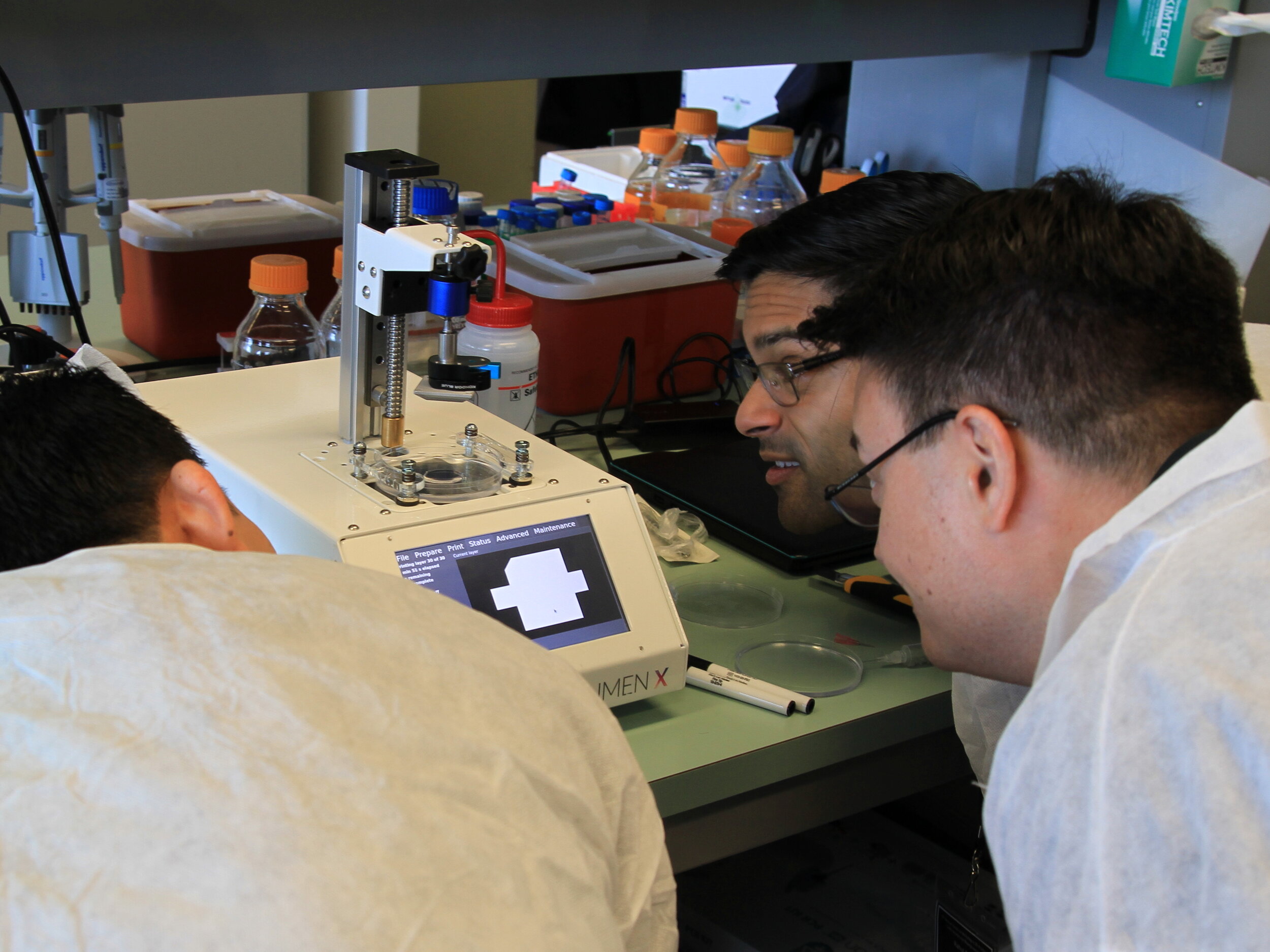

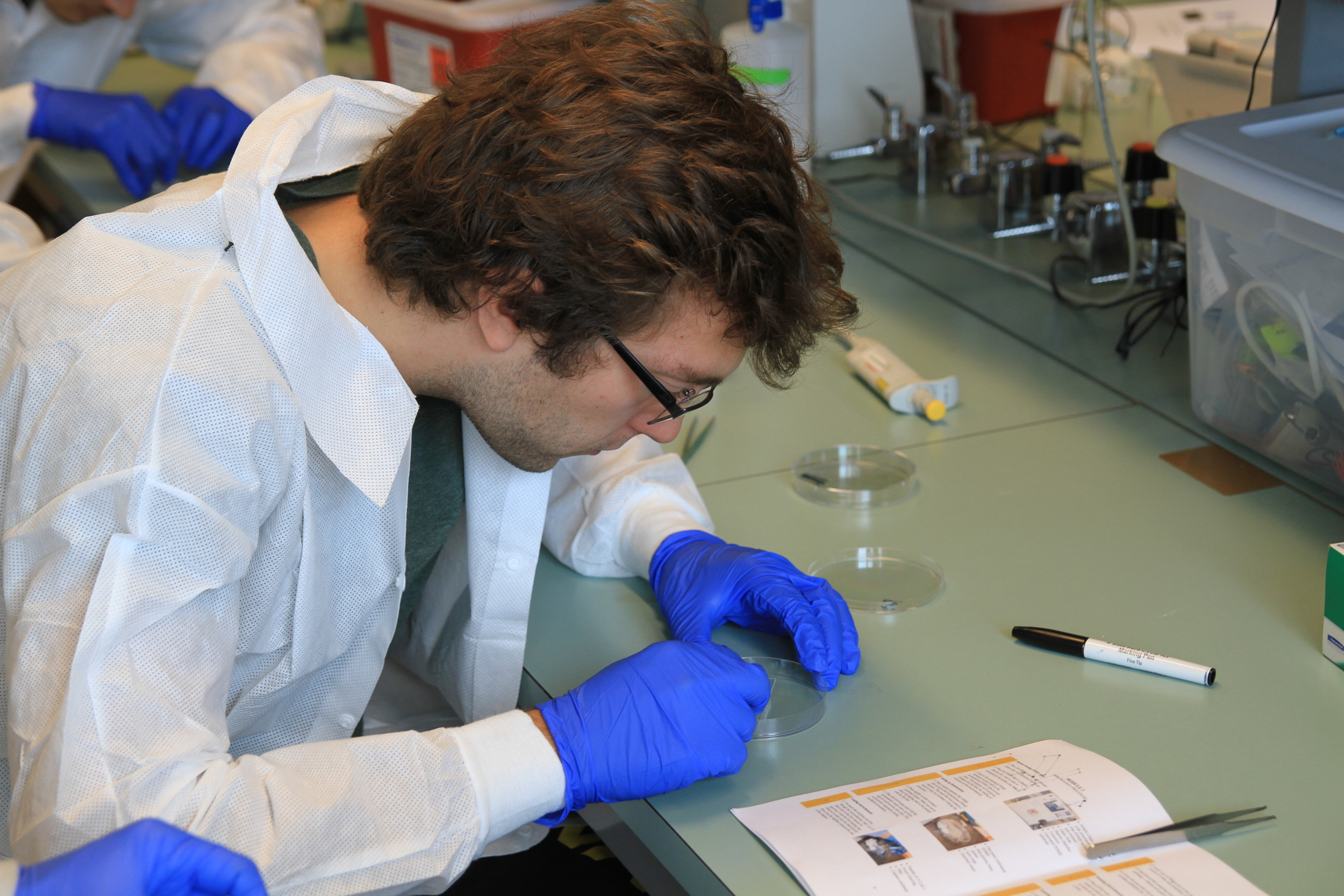

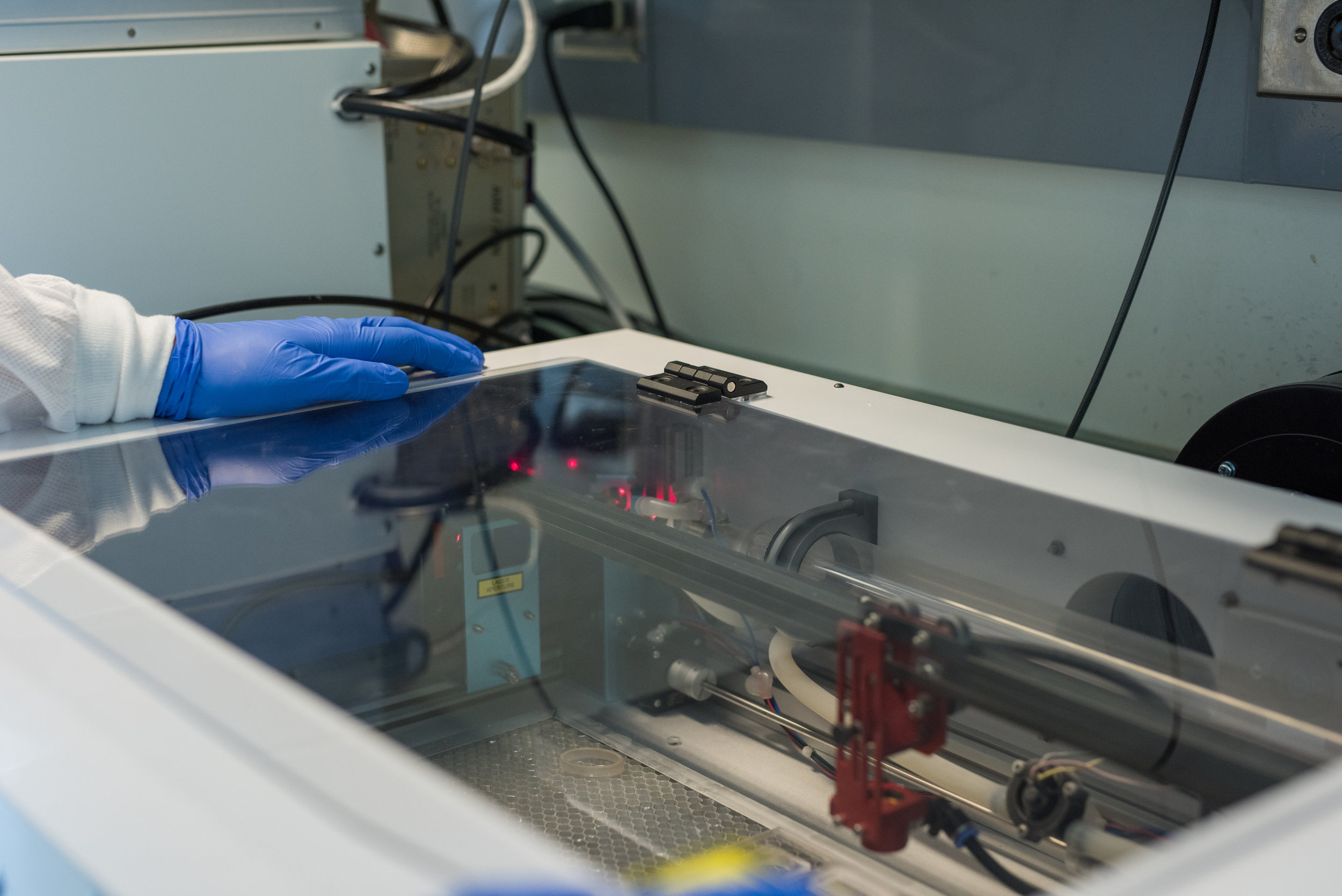

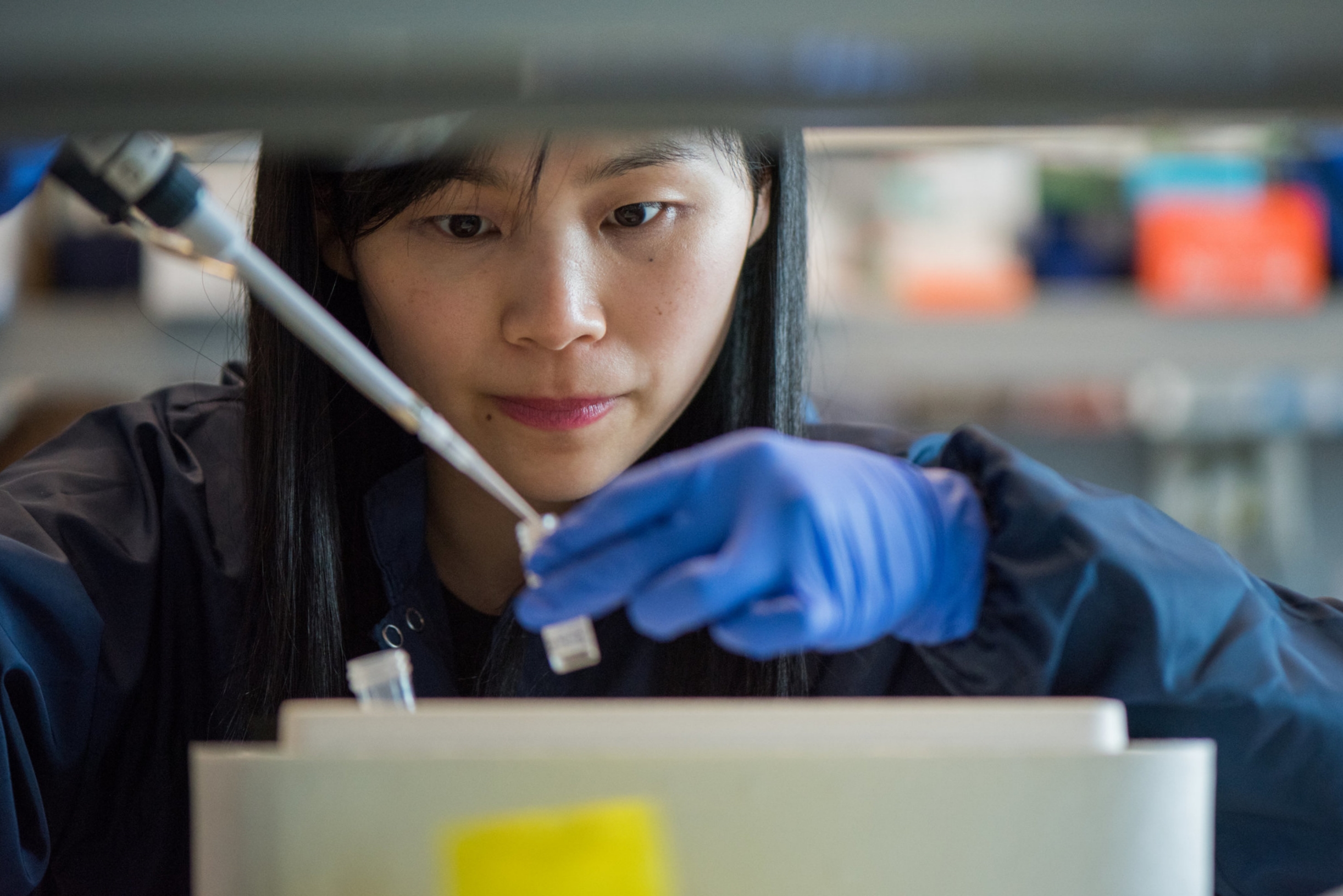

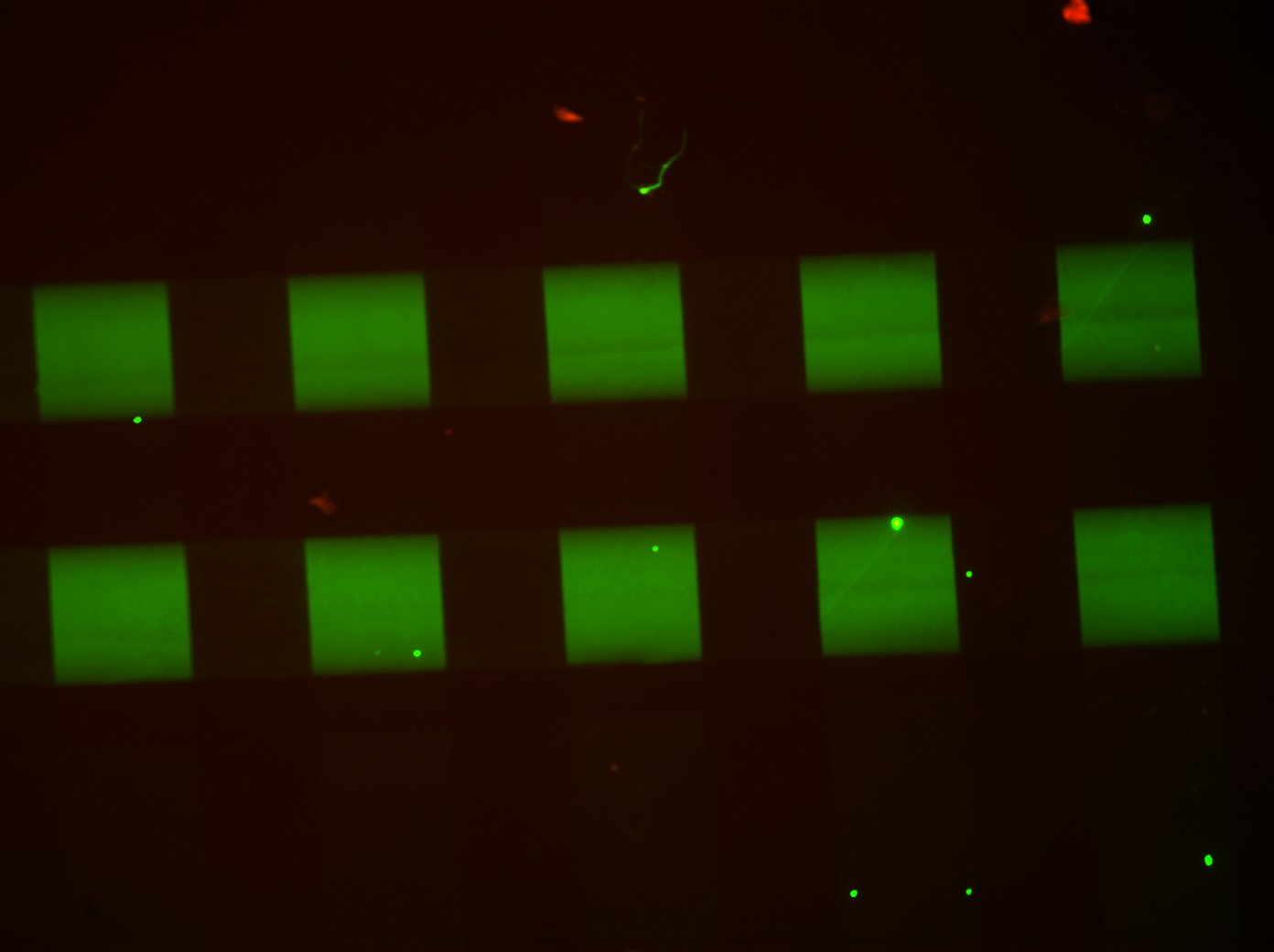

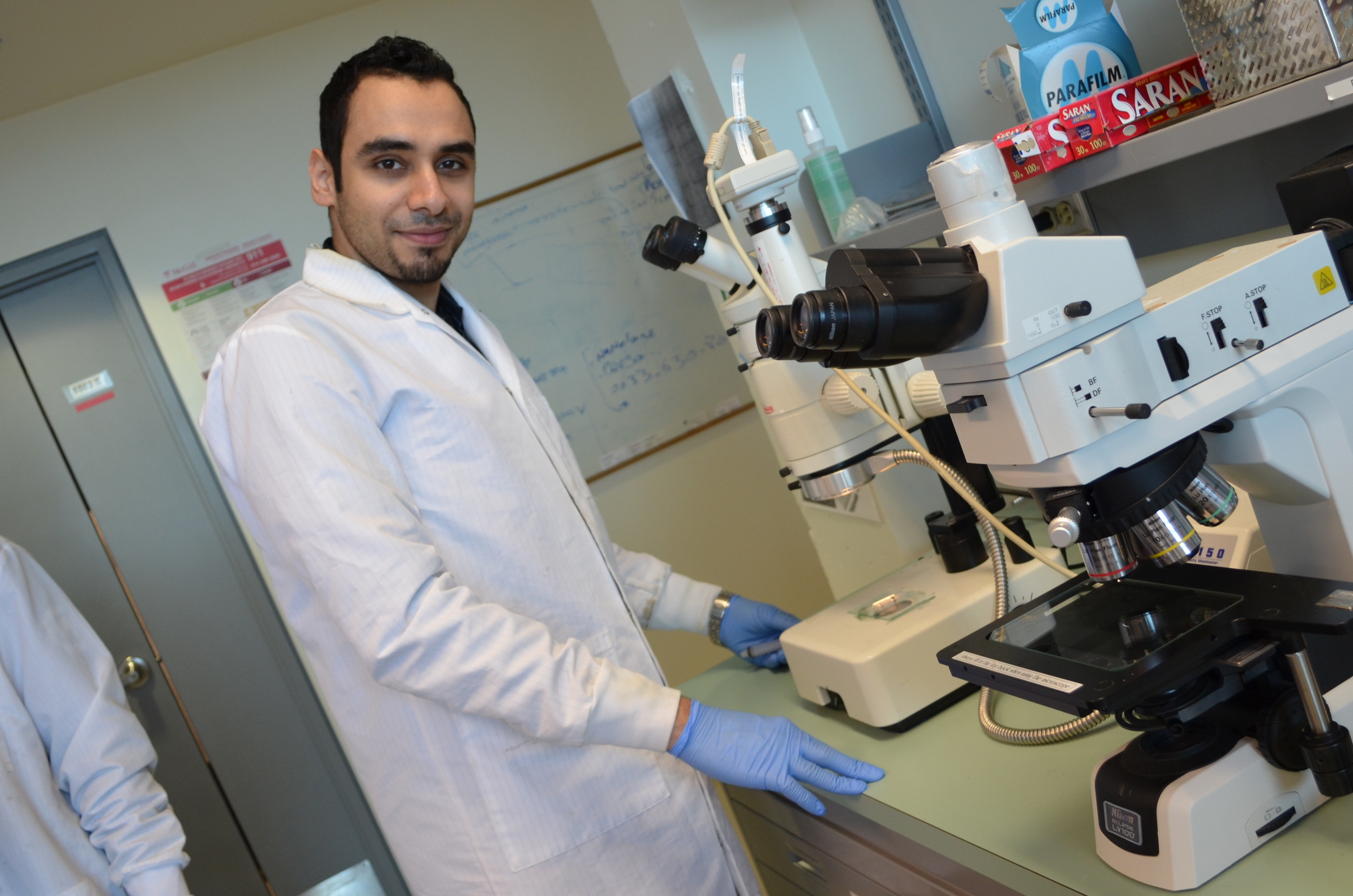

MODULE 3: Hands-on lab session

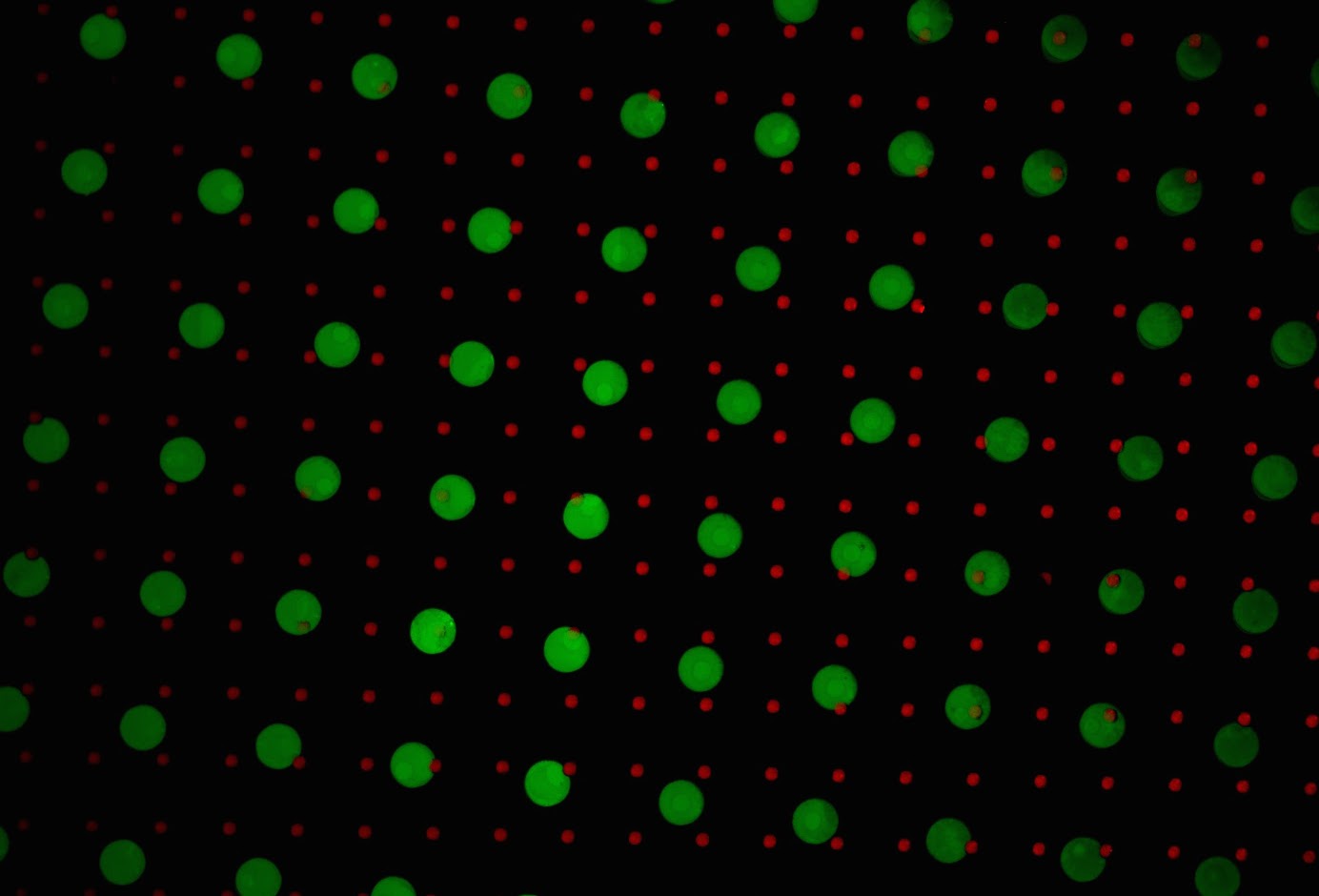

The workshop includes several lab modules in which we complement the lecture topics with hands-on fabrication experience. Participants will be able to directly print functional microfluidic chips and mold PDMS replicates of on-chip cell culture devices. We will seed live cells and image them the next day, such that participants will gain all the experience needed to start the first microfluidic cell culture project in their own labs.

MODULE 4: DESIGN CHALLENGE

In this session, a design challenge premise will be presented to the participants who will be asked to propose a solution that addresses a problem in the field of bioengineering. Presentations will be given by participants who will show how Nano/Microtechnology can be applied to this research area. This session is a highlight of the course as it helps participants to relate what they just learned to a real-world application and receive feedback from our design challenge coordinator and our panel of 3-4 judges during their final presentations. To conclude the workshop, participants will have the opportunity to compete for the best presentation award this year and the results will be announced during the wine and cheese social on the last day!

Jason A. Burdick

Jason A. Burdick, PhD is the Bowman Endowed Professor in the BioFrontiers Institute and Department of Chemical and Biological Engineering at the University of Colorado Boulder. Dr. Burdick’s research involves the design of new biomaterials that can be processed through fabrication methodologies to meet the needs of medicine, ranging from translational therapeutics to tissue models. Jason currently has over 330 peer-reviewed publications and he is on the editorial boards of Biofabrication, Advanced Healthcare Materials, Advanced NanoBiomed Research, International Journal of Bioprinting, and npj Biomedical Innovations. He has been recognized through numerous awards such as a Packard Fellowship in Science and Engineering, an American Heart Association Established Investigator Award, and the Clemson Award for Basic Science through the Society for Biomaterials. Jason has also been elected as a Member of the National Academy of Medicine, a Fellow of the National Academy of Inventors, a Fellow of the American Institute for Medical and Biological Engineering, to the International College of Fellows of Biomaterials Science and Engineering, and an International Fellow of The Canadian Academy of Engineering. He has founded several companies to translate the technology from his laboratory into clinical therapeutics.

JOIN US FOR HIS TALK TITLED ‘Additive Manufacturing of Hydrogels for Biomedical Applications’

Trottier mezzanine

L.M. Trottier Building, Room 2100, 2110

3630 University Street

MD 50

Macdonald Engineering Building, Room 50

817 Sherbrooke Street West

ENG MC 13

Macdonald Engineering Building, Rooms 13

817 Sherbrooke Street West

Genome 6500

McGill Genome Centre, Room 6500

740 Dr Penfield Avenue

Strathcona 2/36

Strathcona Anatomy and Dentistry Building, Room 2/36

3640 University Street

NADIA DAVOUDVANDI

Head Organizer, Sponsorship & Advertisement

HOUDA SHAFIQUE

Design Challenge Master & CAD Teacher

FABIAN SVAHN

CAD Coordinator & Advertisement

Geunyong Kim

Lab Coordinator & Web Master

NOOSHIN KARAMI

Lab Coordinator

JUSTIN DE VRIES

Lab Coordinator & Budget

MOLLY SHEN

Lab Teacher

ANDREAS WALLUCKS

Lab Teacher

JASON ZHU

Lab Teacher & Catering

LAN ANH HUYNH

Catering

BREONA MARTIN

Catering & Sponsorship

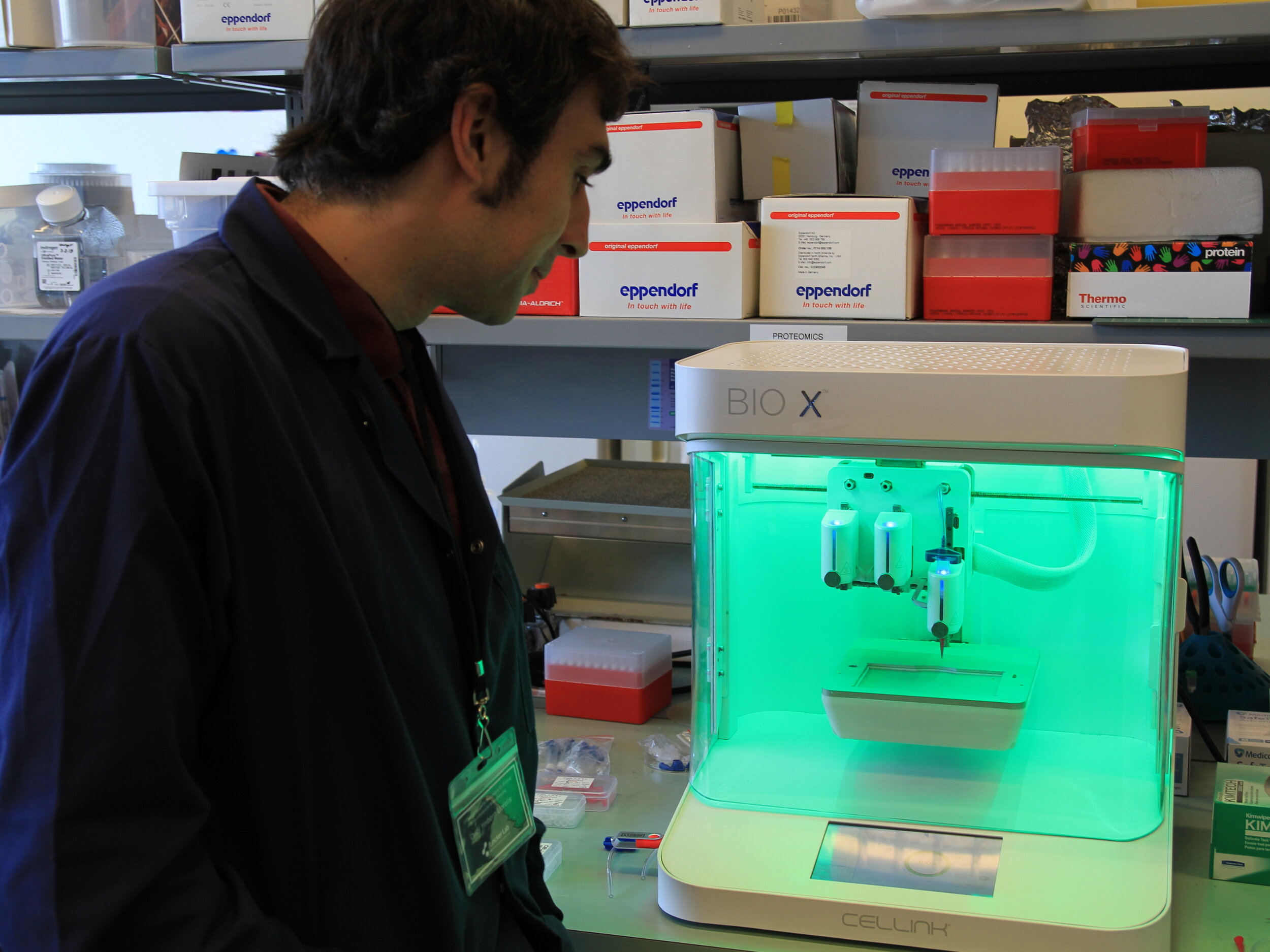

CELLINK is creating the future of health as part of BICO, the world’s leading bioconvergence company. When CELLINK released the first universal bioink in 2016, it democratized the cost of entry for researchers around the world and played a major role in turning the then up-and-coming field of 3D bioprinting into a thriving industry. Today, the company’s best-in-class bioinks, bioprinters, software and services have been cited in over 700 publications and are trusted by more than 1,000 academic, pharmaceutical and industrial labs. At the forefront of the bioprinting industry, CELLINK aims to alleviate organ donor shortage with biofabricated transplantable organs and remains committed to reducing our dependence on animal testing and increasing efficiencies in drug development with more physiologically relevant bioprinted organ models. BICO is listed on the Nasdaq Stockholm Main Market under BICO.

Eden Tech, a French innovator in microfluidics, empowers researchers with advanced tools. Our expertise lies in developing microfluidic tools for precise and controlled experiments. The passionate Eden Tech team tackles societal challenges with this powerful technology. Located in Paris, we leverage France’s rich scientific heritage and global connections. Together, we unlock the immense potential of microfluidics for groundbreaking advancements.

CADworks3D was established in 2018 with the intention of providing exceptional user support, cost effective and microfluidic specific 3D printing solutions. By combining groundbreaking 3D printer technology with an in-house 3D materials development team, CADworks3D are able to provide 3D solutions to the unique needs of microfluidic researchers, startups and established bio-tech firms. The team at CADworks3D brings together over 20 years of experience in CAD, 3D printing and 3D materials development to empower institutions and research labs with the best technical support.

microfludic ChipShop was funded with the mission to shrink the biological and chemical lab and to bring lab-on-a-chip systems into daily laboratory life. Cost efficient, fast and reliable since 2002. Services comprise tailor-made microfluidic systems including instrumentation, microfluidic disposables and assay integration, as well as off-the shelf catalogue products for droplet generation, organ-on-chip assays, micro mixing, sensor integration and many more applications. From design to production, customers are offered everything from one source. All steps take place in the company‘s headquarters in Jena, Germany. The dedicated team offers support from early prototyping to large-scale production, in R&D as well as point-of-care-testing. Besides customized microfluidic solutions, microfluidic ChipShop engages in a multitude of research projects, one of them being UNLOOC, an EU-wide R&D project with 50 partners using organ-on-chip technology to enable the development of more effective medical treatment and reduction of animal testing.

Founded in 2015, ELEGOO is a rapidly developing brand in the global smart manufacturing industry, specializing in R&D, manufacturing, and sales of consumer-level 3D printers, laser engravers, STEM kits, and other smart technology products. With a focus on programming and 3D printing technology, ELEGOO provides unique and smart creation spaces for diverse consumers to enhance personalized experiences.

The Hands-on Workshop in Micro & Nano Bioengineering is made possible through the generous support of our sponsors. To find out more about becoming a sponsor, please email us at junckerlab.workshop@gmail.com.